CNC Machines Services

- Home

- CNC Machines Services

01. Maintenance & Services

Maintenance & Services

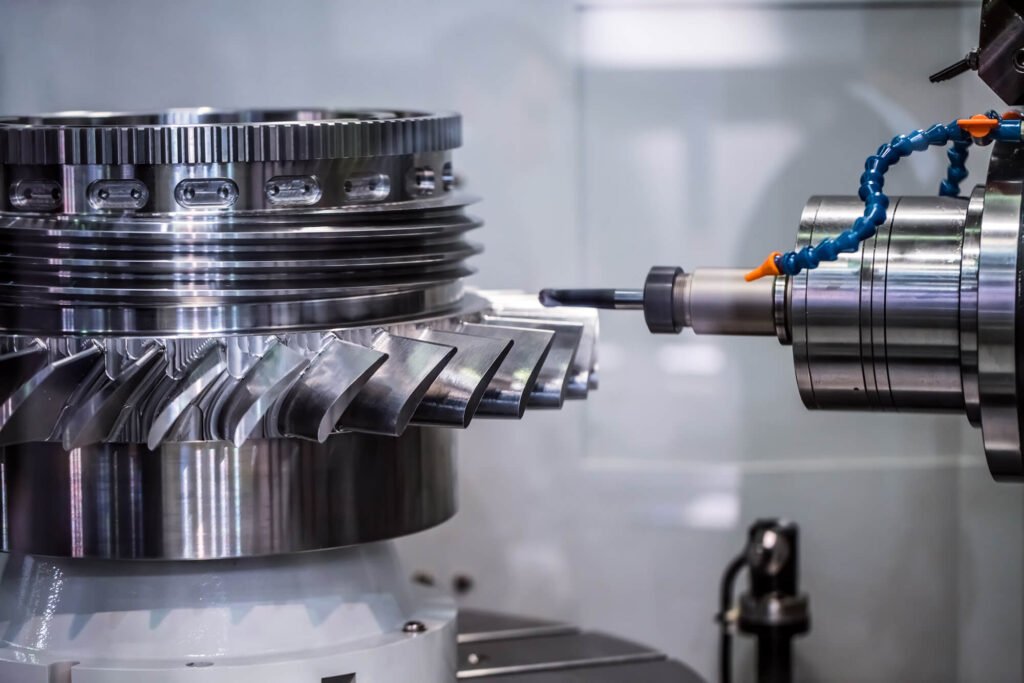

Our comprehensive maintenance services encompass CNC milling and turning machinery, meticulously adhering to or surpassing the specifications prescribed by respective manufacturers. Catered to your unique requirements, our services include:

- Maintenance Consultations: Expert guidance tailored to optimize machine performance and longevity.

- Single-Service Maintenance Requests: Prompt and efficient resolution of specific maintenance issues.

- Full-Service Scheduled Maintenance Plans/Subscriptions: Regular, proactive servicing to maximize machine availability and operational efficiency.

Through our unwavering commitment to delivering exceptional service, we empower our clients to achieve optimal machine performance, ensuring increased productivity and profitability.

Our comprehensive maintenance services encompass:

- Scheduled Maintenance Plans: Proactive inspections and maintenance to optimize uptime and performance.

- Drive Optimization: Analysis and enhancements to improve drive efficiency and reduce downtime.

- Geometry Verification: Precision measurements and adjustments to ensure optimal system operation.

- Adjustments and Calibration: Fine-tuning and calibration of equipment for enhanced precision and accuracy.

- Full Equipment Reconditioning: Overhaul and restoration of equipment at on-site or remote facilities to prolong its lifespan and restore its original performance capabilities.

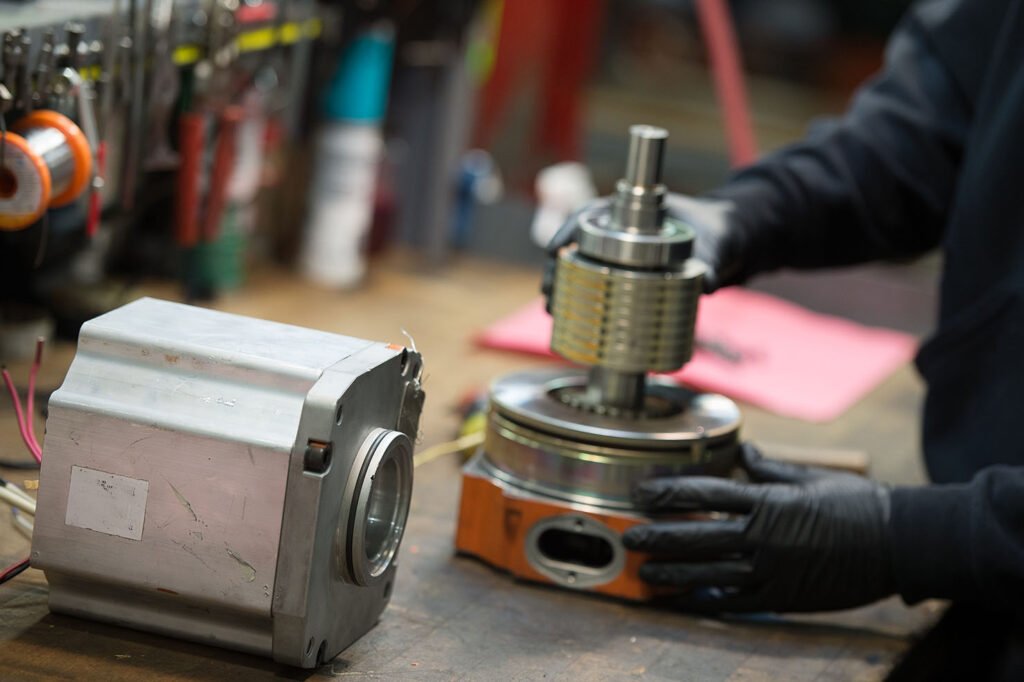

Repair

All reputable CNC service providers are aware that both components and machines inevitably fail over time. Our extensive expertise in maintenance and service has equipped us with an equivalent level of proficiency in repair.

Our repair services encompass:

- Mechanical and electronic component repair

- Spindle repair

- Replacement of original equipment manufacturer (OEM) parts

- Pump repair

- Scale repair

- Hard drive repair and replacement

- Realignments

As with our maintenance and servicing, all repaired parts are fully warranted.

02. Machinery Installation

We provide highly skilled technicians who have received comprehensive factory training and are fully qualified to install your equipment according to exacting manufacturer specifications.

We ensure that all installations strictly adhere to established factory protocols and best practices.

Our installation services are tailored to meet the unique requirements of your facility, accommodating both standardized and customized approaches to optimize operational efficiency.

Upon completion of the installation process, our highly skilled technicians will meticulously re-evaluate the established protocols to ascertain the precision of the installation, thereby ensuring the optimal performance and efficiency of your CNC machine.

03. Retrofit

Machine retrofits are feasible at various degrees of complexity. A basic retrofit may involve replacing ancillary components such as older accessories or introducing new optional features. More comprehensive retrofits could encompass the replacement of critical machine components including axes motors, spindles, drives with advanced AC digital servo technology, software, and hardware upgrades. Additionally, retrofits may address essential aspects such as clamping/holding mechanisms, feeding systems, and tooling enhancements.

A comprehensive retrofit entails the meticulous replacement of the machine’s electrical system, incorporating advanced components such as a CNC control unit, AC digital servo motors and drives, comprehensive machine wiring, linear and rotary encoders for closed-loop positioning feedback, a state-of-the-art operator pendant, and a redesigned electrical cabinet.